CodeMark (Australia) Approved

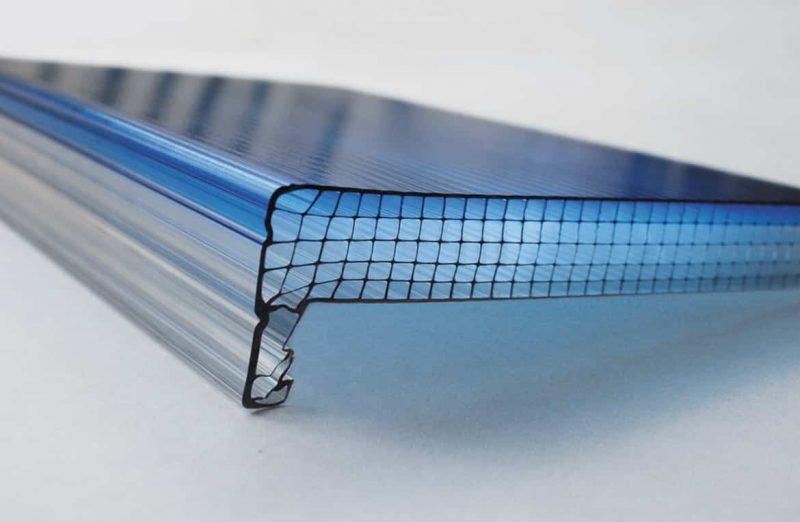

Danpalon® Microcell panels are made from the highest quality resin and are co-extruded onto both external sides of the panel with market-leading UV protection technology invented by Danpal. This ensures superior colour stability, longevity and durability, as well as the highest possible production quality resulting in CodeMark accreditation through SAI Global.

Low Conductivity, High Insulation

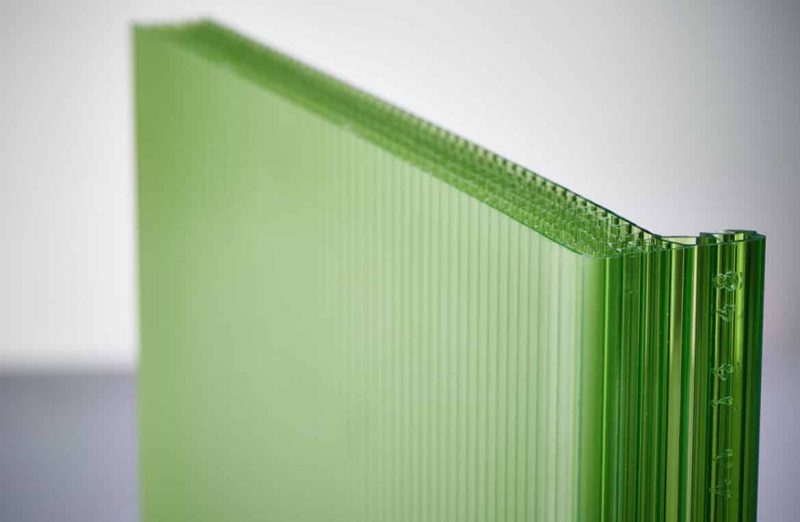

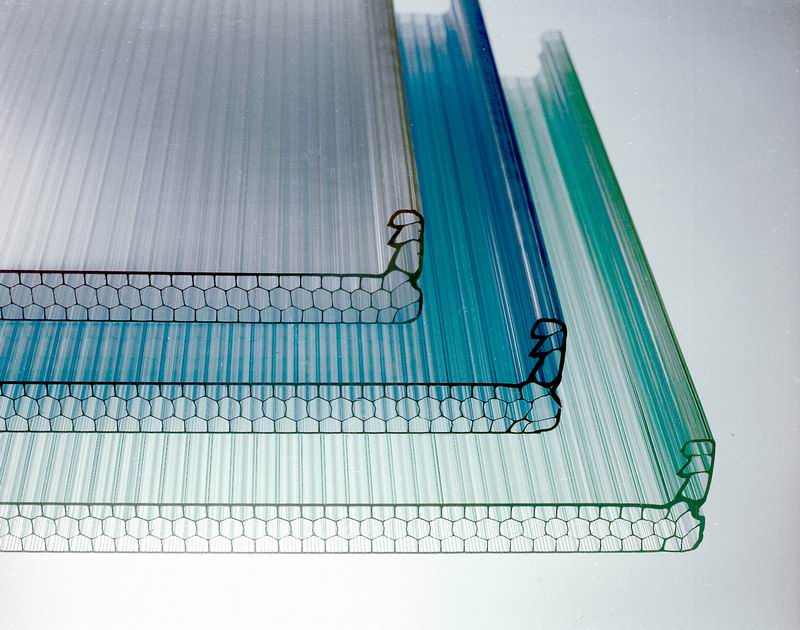

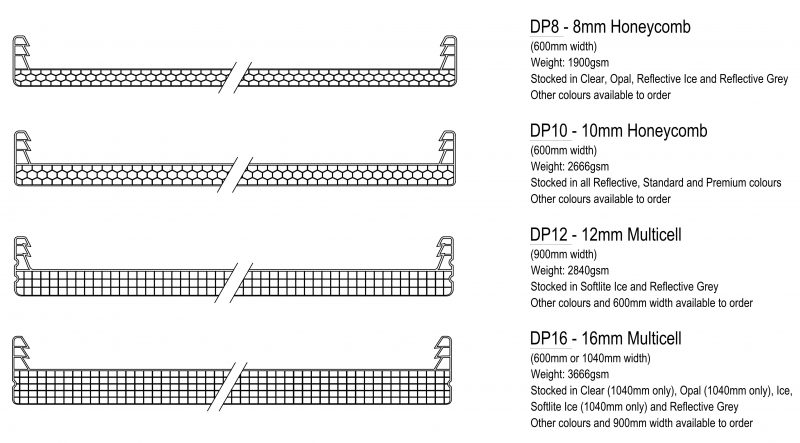

All Danpalon® Microcell panels are manufactured with more cells and layers than traditional panels. In fact, our panels have ten times the number of cells than the standard sheet on the market. Thanks to their fine microcell structure, we get better thermal insulation through significantly lower thermal conductivity and exceptional ventilation.

Impact and Weather Resistant, Durability

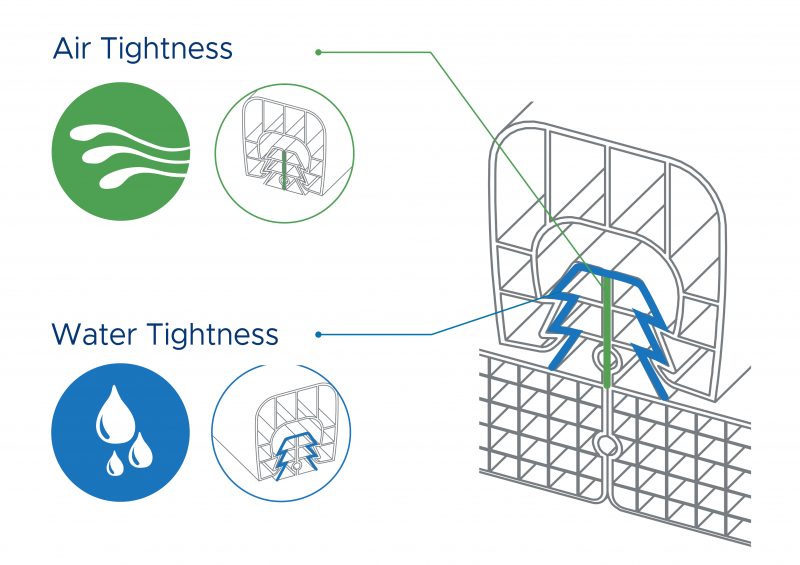

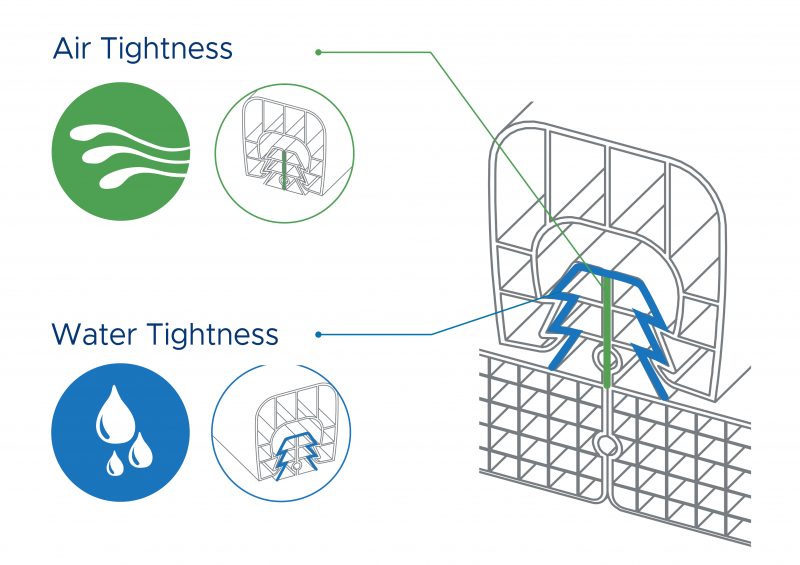

The unique standing seam edge on Danpalon® panels give added strength, and air and water tightness, while the density from the additional layers and cells makes Danpalon® stronger against hailstones and other small objects.

Compared to classic alveolar panel structures and other open-celled products, the minimal space and tight ribbing between the vertical supports of the Danpalon® Microcell structure offers the highest resistance to impact and hail damage. The high concentration of cells provides Danpalon® microcell panels with improved mechanical properties and rigidity.

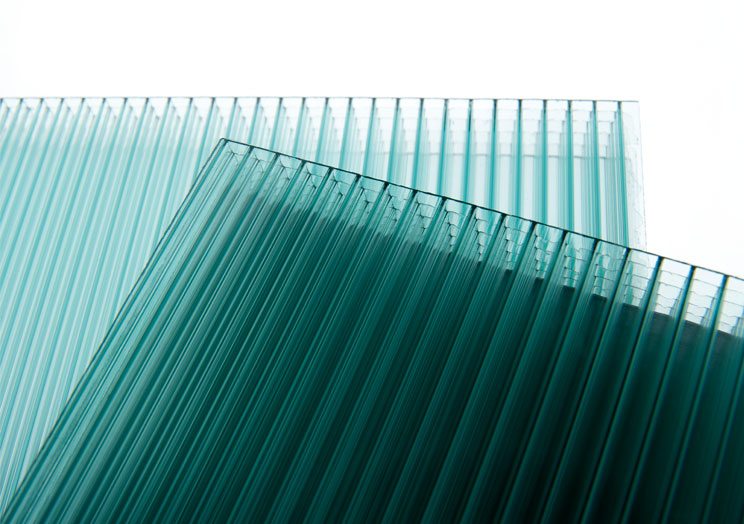

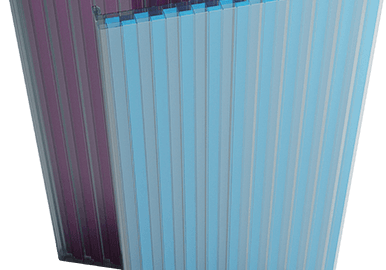

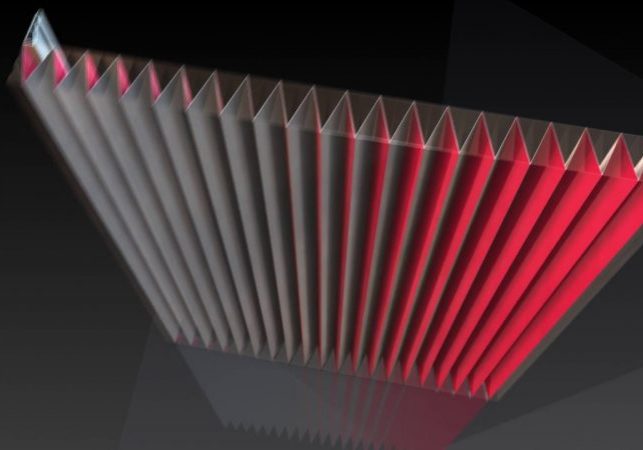

Effortless Daylighting and Light Diffusion

Danpalon® contributes to optimal efficiency and significant savings in energy costs. The microcell structure transmits an even diffusion of natural light, producing a rich look and comfortable ambient space. Specifically designed for architectural daylight applications, the tight spacing between the ribs produces an exceptional quality of light and a unique iridescence – reflecting and dispersing light in a way unmatched by any other material.